RFID Waste Management

- Home

- Pages

RFID Solution For Waste Management

Each waste bin or bucket has an RFID tag attached to it. Every garbage truck has an RFID reader attached to it. When the waste bin is lifted and emptied into the truck, the truck reader reads the RFID tag and transmits this data to the wireless handheld in the truck driver’s cabin. This data is encrypted and cannot be viewed by the staff. At the end of the route, the data is transmitted to the central server, where any supervisor or manager can view it. This data will include garbage bin number, collected at what time & date, who was the garbage collector ( assigned to the truck) & so on. This vastly improves the traceability of the trucks and allows the authorities to monitor & improve the productivity of this activity. It makes the entire garbage collection function, very transparent.

Present Situation Of Waste Management:

Waste Management In many countries today, the local authorities, or the contractors appointed by them, are responsible for the collection of garbage from urban neighborhoods. Every urban neighborhood has a large garbage bin allocated to it. Residents or their domestic helpers, typically carry their garbage to these collection bins. Alternatively, garbage collection personnel collect garbage door to door and then dump it in these large bins. These large bins are then carried away by personnel traveling along with the garbage trucks. The truck will typically have a fixed route every day. It will lift the large filled garbage bin, empty its contents into the truck, and keep the empty bin again at the same place. There will be hundreds of such trucks along different routes every day.

Problems With The Present System

- Tracking these trucks and the personnel who man them is a problem for the local authorities. There is no way to monitor that garbage has been collected every day.

- No way to verify the time taken to travel along every route, or to verify the time taken to collect say x number of bins of garbage every day.

- No way to verify whether the staff appointed for the job are really busy or do only half the bins in a day that can be easily done.

Future Scenarios Of Waste Management

In Europe, a municipality in Greece has already implemented such a system and more are likely to follow. The attractiveness of the system will make other local city councils and municipal authorities to implement these kind of systems. It will improve governance, and cleanliness and ultimately help the ecology. The ROl is very good, given the returns are not just in X dollars, but also have environmental side benefits.

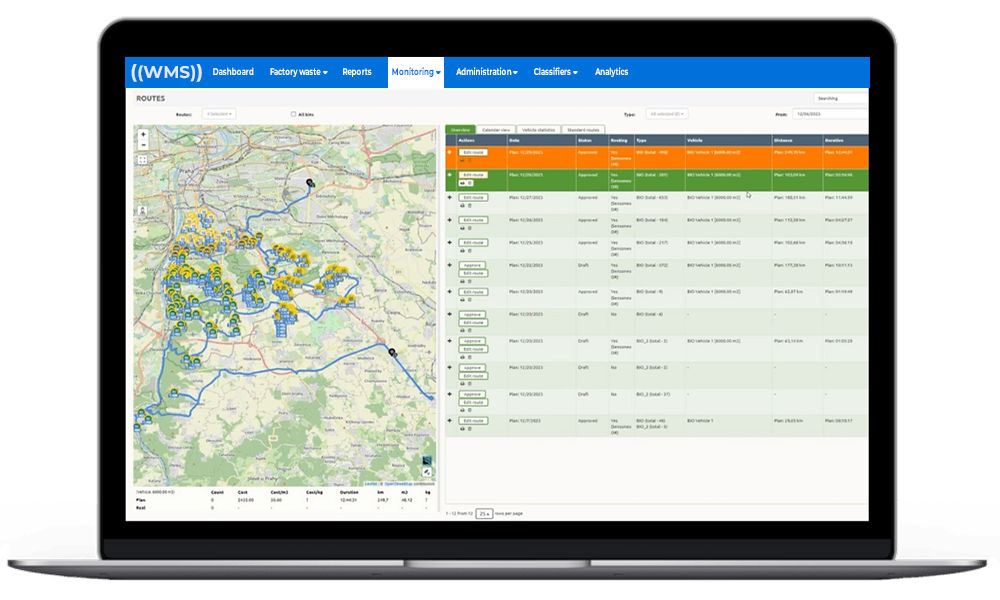

Smart Waste Management Software System

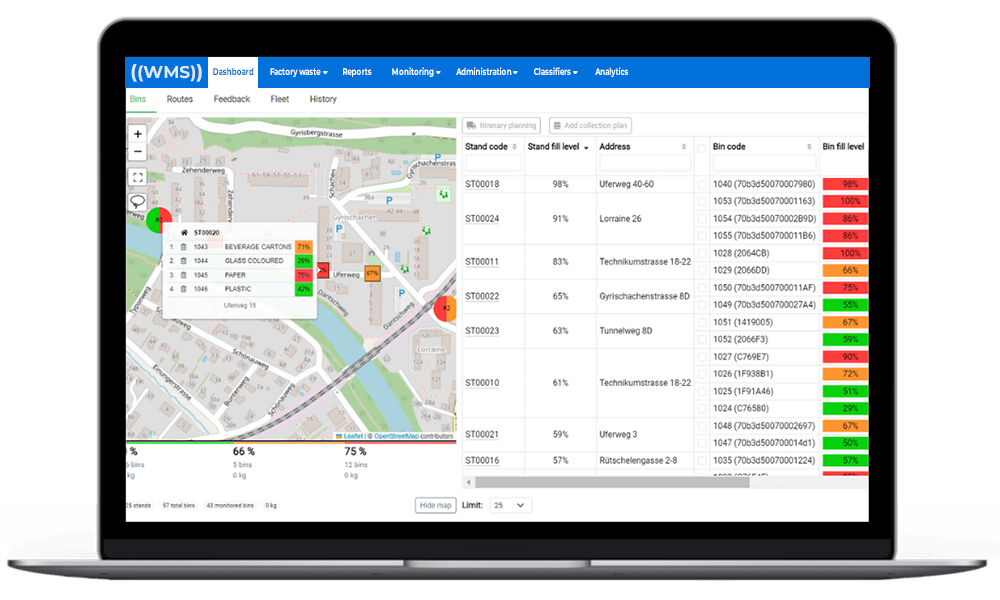

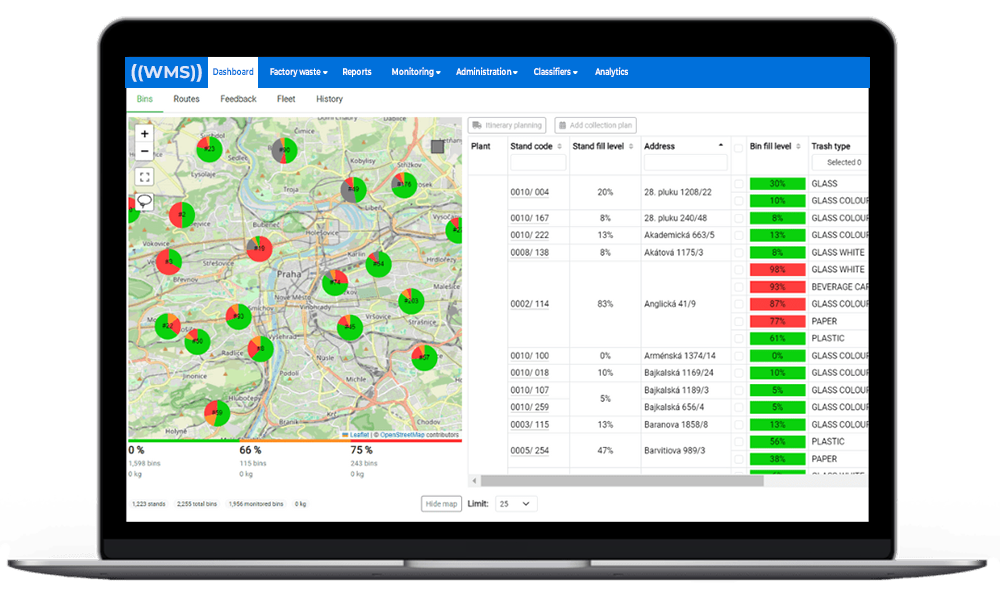

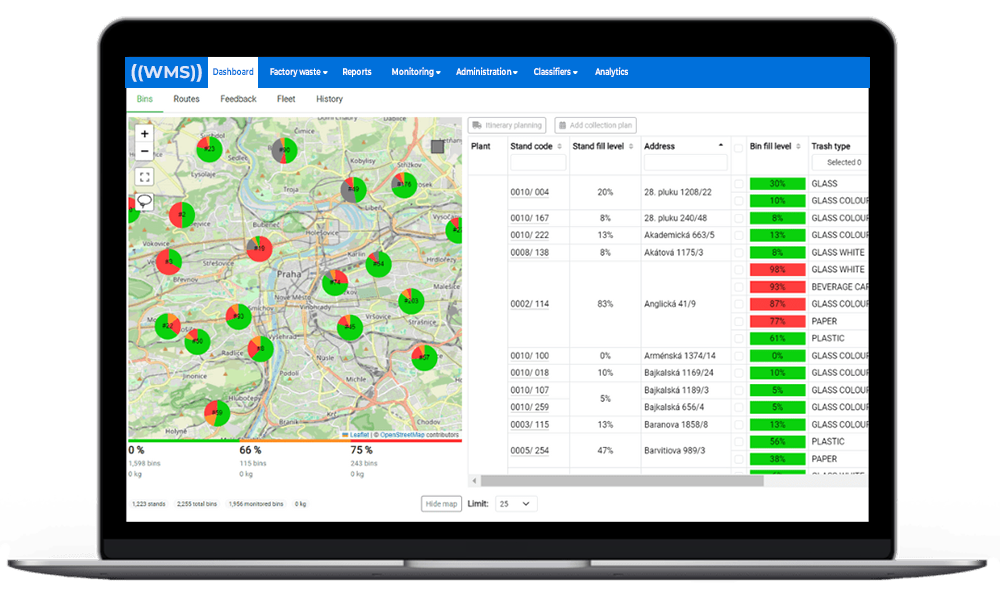

The powerful cloud-based platform helps customers to configure, monitor, and plan everyday waste management activities and belongs to one of the best waste management software on the market these days. The customer sees all the bins on a digital map and via street view including capacity, waste type, last measurement, GPS location, and collection schedule or pick recognition.

You can build a detailed bin inventory, optimize bin location (capacity, cost), record maintenance evidence. For bins with Smart sensors, you can set up and configure sensors, monitor real-time fill levels, see predictions, plan collection routes, see pick reports, and deal with reports from citizens.

Waste management software system is available in more than 10 different languages and you can integrate smart waste data to your current IS via API.

- Detailed bin inventory

- Digital interactive map

- Sensor configuration

- Live data from sensors

- Future predictions on fill levels

- Citizen feedback

- Different notifications – full bin, fire and tilt alerts

- Itinerary planning for waste collection

Detailed bin inventory:

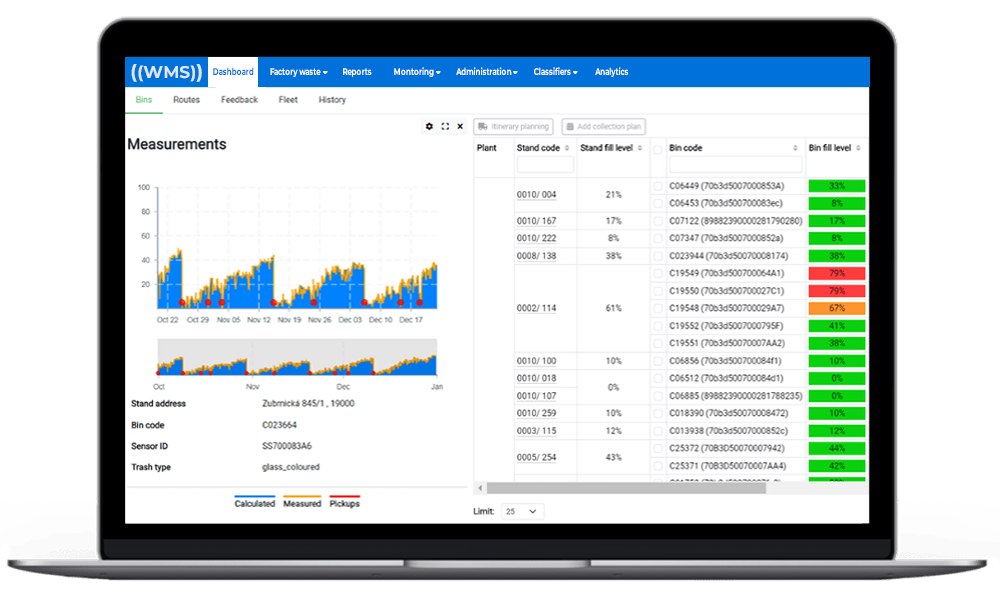

All monitored bins and stands can be seen on the map. Stands are color-coded within clusters based on predefined thresholds. This color scheme visually communicates the fill levels, aiding users in identifying areas with containers reaching their capacity. You can see bin details in the Dashboard – capacity, waste type, last measurement, GPS location and collection schedule or pick recognition.

Real-time bin monitoring:

The Dashboard displays real-time data on fill-levels of bins monitored by smart sensors.

In addition to the % of fill-level, based on the historical data, the tool predicts when the bin will become full, one of the functionalities that are not included even in the best waste management softwares. Sensors recognize picks as well; so you can check when the bin was last collected.

With real-time data and predictions, you can eliminate the overflowing bins and stop collecting half-empty ones.

Plan waste collection routes:

The tool semi-automates waste collection route planning. Based on current bin fill-levels and predictions of reaching full capacity, you are ready to respond and schedule waste collection.

You can compare planned vs. executed routes to identify any inconsistencies.

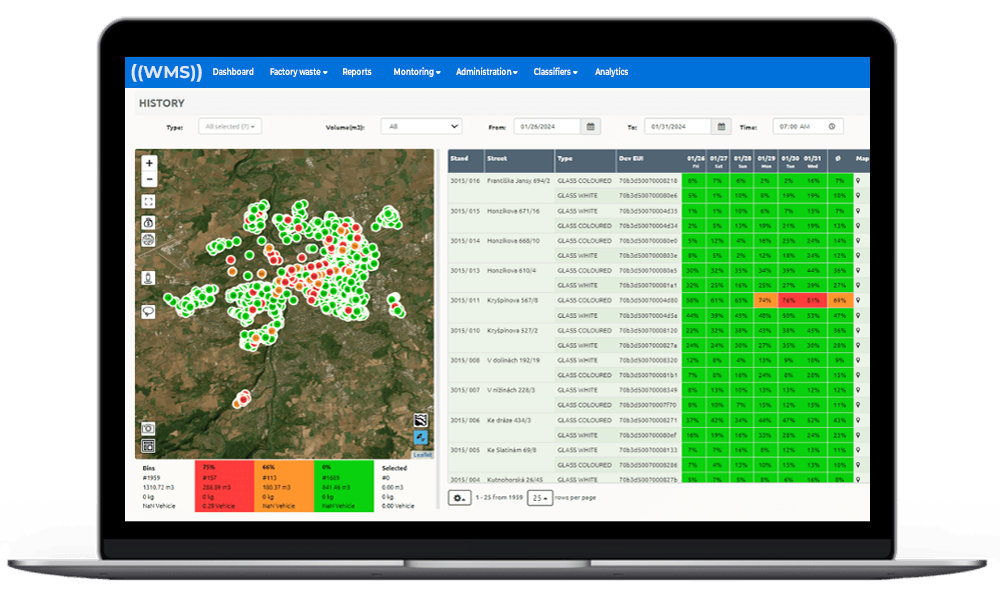

Understand filling cycles:

What is the filling cycle for the bin? Find a bin on the map or in the dashboard, and access a filling graph to see its filling cycles and picks over the last few weeks.

If it gets full very fast, you might consider increasing capacity to save collection costs.

Eliminate unefficient picks:

Eliminate the collection of half-empty bins. The sensors recognize picks. By using real-time data on fill-levels and pick recognition, we can show you how full the bins you collect are.

The report shows how full the bin was when picked. You immediately see any inefficient picks below 80% full.

Analyze the data:

Analytics module with a detailed PowerBI report covering collections, measurements, average fill rates, diversion rates, and collection frequencies helping customers to evaluate the effectiveness of all these key KPIs, including recommendations adjustments, and process optimization.

- Fire alarm and other warnings: Sensors send data on battery status and have a built-in fire alarm. You can see all the warnings on the Dashboard and/or send SMS or Email notifications to the responsible people.

- Mobile App for drivers and operators: We understand that waste collection professionals spend a lot of time outside and welcome anything that makes their jobs easier. Therefore we have developed the mobile application, which is tailored to their specific needs and enables quick and convenient usage.

- Pickup Recognition: Sensors have built-in motion detection and recognizes when was the bin emptied. Dashboard provides both data-driven and sensor-driven pickup (emptying) recognition.

- RFID Fixed Asset Management

- RFID Anti-Theft Systems

- RFID Jewellery Tracking System

- RFID Untouched Attendance

- RFID Warehouse Management

- RFID Animal Identification

- RFID Vehicle Identification

- RFID ETC(Electronic Toll Collection) Solution

- RFID Laundry Management

- RFID Student/Parent Auto Voice Calling at School

- RFID Royalty Customers Deals at Shopping Malls

- RFID Document Management

- RFID Anesthetic Dosages

- RFID Baggage Handling

- RFID People & Personnel Tracking

- RFID Blood Banks

- RFID Car manufacturing

- RFID Drug Pedigree

- RFID Event Management

- RFID Race Solution Sports Events

- RFID Food Safety

- RFID National Identification

- RFID Gasoline Dispensing

- RFID Hotels & Resorts

- RFID Work in Progress Tracking

- RFID Hospital Stores Management

- RFID Medical Surgeries

- RFID Based Patient Location Confirmation

- RFID Body Temperature Monitoring System

- RFID Body Temperature Monitoring for Employees

- RFID Mother Baby Pairing

- RFID Museums

- RFID Spool Tracking System

- RFID Plane Spare Parts

- RFID Industry 4.0 Smart Manufacturing

- RFID Container Tracking System

- RFID Intelligent RFID Parking System

- RFID Office Printers & Cartridges

- Real Time Location Tracking (RTLS)

- RFID Retailing

- RFID Underground Sewers

- RFID Forklift Automation

- RFID Sales Staff Tracking at Shopping Malls

- RFID Trial Room Analytics at Shopping Malls

- RFID Traffic Management

- RFID Guard Patrolling System

- RFID Weightbridge Automation System

- RFID E-Lock for Contrainers

- RFID E-Seal for Contrainers

- RFID Waste Management

- RFID Yard Management

Can we help you?